Introduction

Diamond abrasives represent some of the best cutting and grinding tools available for the concrete, asphalt and stone industries. Selecting the right tool for the job can often be a challenging task, so here are some basics to get you started on diamond abrasive blades uses and applications.

BLADE CONSTRUCTION

First, it is important to understand what a diamond blade is. Diamond blades are comprised of diamond impregnated segments attached to steel core. They are used to cut cured concrete, green concrete, asphalt, brick, block, marble, granite, ceramic tile, or just about anything with an aggregate base. The segments are formulated with synthetic diamond particles mixed in precise amounts with powdered metals that compose the bond. Diamond particle size and grade are tightly controlled and optimized for the intended application. The formulation step is critical to the design and performance of a diamond blade. The mixture of powdered metals (the bond) significantly affects the cutting ability of the blade in various materials. This mixture is poured into a mold, compressed and heat treated to form the segment. Segments are attached to the steel core by laser welding, sintering or silver brazing. The working surface of the blade is dressed with an abrasive wheel to expose the diamond particles. The blade core is tensioned to ensure stability and straight cutting. The final step is painting and adding the safety labeling.

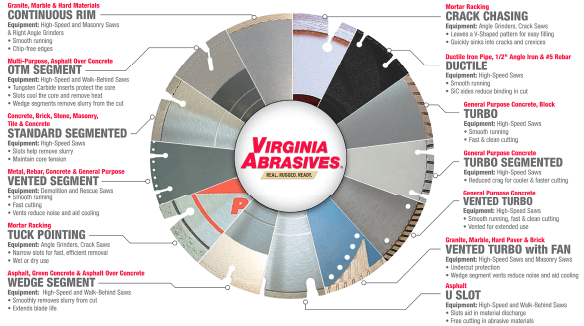

Diamond blades work in a grinding or chipping action. The synthetic diamond particles collide with the material being cut, breaking it down and removing the material from the cut. Diamond segments come in different designs such as standard segment, turbo, wedge or continuous rim. The different configurations optimize the desired cutting action, enhance cutting rate and prolong the life of the diamond blade.

Learn more about they types of segments and their uses: Click here to view an interactive blade wheel

THE BOND

Selecting the proper bond in a diamond blade is very important to ensure optimal cutting performance. The difference between a cured concrete diamond blade and an asphalt diamond blade is in the composition of the bond used to hold the diamonds in suspension. Since the diamond is doing the cutting, the bond must wear down to continually expose new sharp cutting diamonds.

Cured concrete is a hard, dense material, therefore the bond in a cured concrete blade is considered to be a soft bond. It is designed to continually expose new diamond cutting particles. All of our concrete blades are designed to encounter reinforcement of one form or another. Mesh or rebar will slow the cutting rate down a small amount. Let the blade do the work, there is no need to add additional pressure. Asphalt is a soft, abrasive material. The hard bond on an asphalt cutting blade is designed to resist wear and hold the diamond particles in place. This ensures efficient diamond cutting action and maximum blade life.

DIAMOND BLADE APPLICATION

In order to determine the best diamond blade for the job, make sure to answer these important questions:

- What kind of saw is being used – high speed or walk behind (high or low horsepower)?

- Will the cutting be done wet or dry?

- What kind of material is being cut – cured concrete, green concrete, asphalt or asphalt over concrete?

- What level of performance do I need - higher quality diamonds may cost more, but offer greater cutting performance, life and overall value?

USING THE WRONG BLADE

If a concrete blade is used to cut asphalt, the bond will wear quickly and the blade life will be short. The reverse is true if using an asphalt blade to cut concrete. The exposed diamonds will wear but the bond will not. The cutting surface of the diamond segments will polish and glaze over. When the bond does not erode, no new diamonds become exposed, eventually causing the blade to stop cutting, overheat, and eventually result in damage to the segment and/or the core.

DIAMOND BLADE USE AND SAFETY

- Install the diamond blade correctly on the machine, making sure that the directional arrow on the blade matches the arbor rotation on the saw.

- Always use properly adjusted blade guards when operating saws.

- Always wear proper Personal Protective Equipment – eye, hearing, respiratory, gloves, feet and body.

- Always comply with OSHA regulations by using approved dust control measures (supply water to the saw).

- When wet cutting, ensure that there is adequate water supply. Insufficient water supply can lead to blade overheating and failure of the segment or core.

- If using a high-speed saw, do not make long continuous cuts with a dry diamond blade. Periodically remove the blade from the cut for a few seconds and allow it to cool.

- Never force a diamond blade into the workpiece. Allow the diamond to cut at its own speed. If cutting particularly hard or deep material, “step cut" by cutting 1" at a time.

- Do not allow the diamond blade to cut through the concrete or asphalt into the “sub base" material, as this will result in excessive wear and failure of the blade.

- Never use a damaged blade or a blade that exhibits excessive vibration.

We are a US Manufacturer. Fast, free shipping.

We are a US Manufacturer. Fast, free shipping.