Abrasive material types used in Virginia Abrasives product vary based on the intended use of the product.

Virginia Abrasives produces a wide range of abrasive products, including sandpaper, abrasives discs, and coring and grinding tools. Our specialty is products used in wood and industrial flooring surfaces.

This a general overview of common abrasives used in our products and their typical best uses.

-

Aluminum Oxide (A/O):

- Virginia Abrasives products using aluminum oxide are likely suitable for a variety of applications. A/O is a versatile abrasive that can be used on wood, metal, plastics, and other materials.

- Best Used For: General-purpose sanding, stock removal, surface preparation, and finishing on a range of materials.

- Recommended Market: Rental Machines

-

Silicon Carbide (SiC):

- Premium Pro abrasive products feature silicon carbide on paper, cloth, or hook-and-loop backing and are designed for longer use or harder materials or specialized applications. Silicon Carbide is often valued for the resulting scratch patterns in hardwood floors.

- Best Used For: Sanding and polishing hard materials such as glass, stone, granite, and concrete. Also effective for wet sanding applications and often used by professionals due to its durability.

- Recommended Market: Professional Floor Refinishing

-

Zirconia Alumina:

- Z-Kut™ Zirconia alumina abrasives are known for their toughness and durability, making them suitable for demanding applications and extended use in a professional setting.

- Best Used For: Heavy-duty grinding, weld removal, rust removal, and other aggressive material removal tasks, particularly on metal surfaces. Z-Kut™ belts can be washed and reused to extend the life of the product.

- Recommended Market: Professional Floor Refinishing

-

Ceramic Alumina:

- Ceramic abrasives are exceptionally hard and are designed for high-pressure applications requiring efficient material removal.

- Best Used For: Grinding and shaping hard metals, stainless steel, and other challenging materials.

- Recommended Market: Professional Floor Refinishing

-

Aluminum Oxide (A/O) and Silicon Carbide (SiC):

- Some products, like Cut-Off wheels, use a combination of abrasives depending on the item that they will be used to cut.

-

Diamond:

- Diamond blades, core bits, grinder tooling and polishing pads offer industrial diamond abrasives for more advanced applications, superior cutting and extended durability

- Best Used For: Grinding, honing, and polishing extremely hard materials like concrete, stone, and ceramics. Recommended Markets: Industrial, Hardscape, Concrete, Asphalt and other flooring

-

Other Specialized Abrasives:

- Many companies offer a wide range specialized products for specific industries or applications, such as abrasives optimized for woodworking or automotive refinishing.

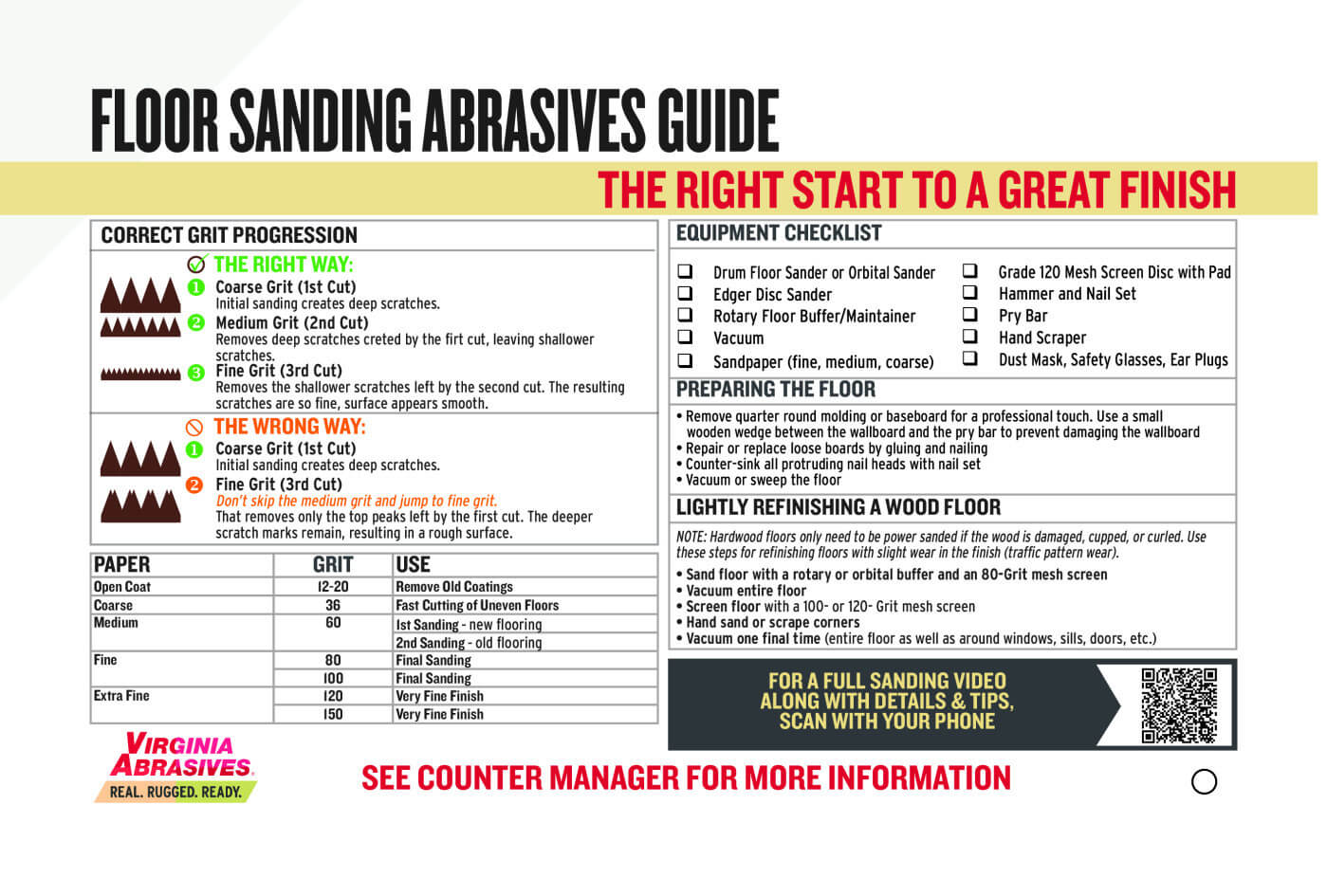

When using Virginia Abrasives products or any sandpaper with different abrasives, it's essential to consider the material you're working on, the desired finish, and the level of aggressiveness needed. Always follow the manufacturer's guidelines and product recommendations for the best results. Different grit sizes will also affect the outcome, with lower grits being more aggressive for material removal and higher grits providing smoother finishes.

For accurate and specific information about Virginia Abrasives products, including our abrasives and their best uses, visit VirginiaAbrasives.com or contact Virginia-based customer support team at 800.446.1805 for the most up-to-date information.

We are a US Manufacturer. Fast, free shipping.

We are a US Manufacturer. Fast, free shipping.